Is lake city brass hard on the dies and where could I go to find something that will cut the brass fast? Any help and advice is much appreciated

LC is not any harder on dies then any other. The time brass is any harder is when it is not clean and even then it takes a LOT of use to make them non useable. There are tons of methods to convert 223 into 300BLK. The best way really depends on what tools / equipment you currently have and how many you are wanting to convert.

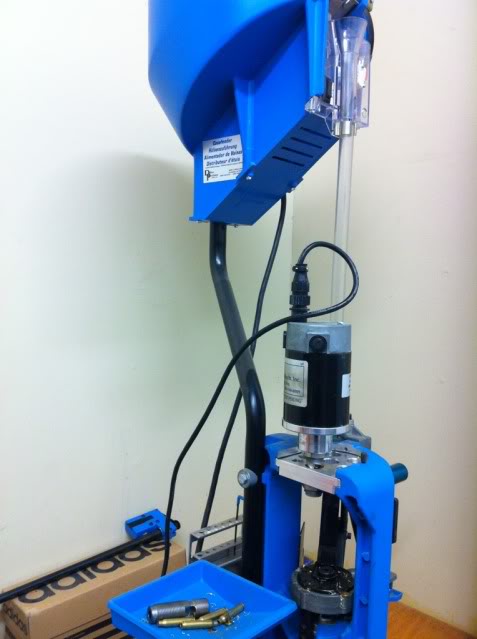

A hack saw or Dremel works fine for a handful. If you want to do thousands then you might want a dillon trimmer