Yes. I dropped it and broke the hopper last night, but I glued it back together... I just thought this one was better... more enclosed, less bulky. I dunno.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I feel your pain.. order one ,, you will get many years uf use from it.. I wish i had more of them so i did not have to change discs and remove dies to change it out to another size.

I do not know what powder you are using but the regular auto disc works very well with bullseye and 231 as far as i know.

But like i stated earlier i modified it.

I closed up the clearances and I also enlarged the hole where the disc moves to to drop the powder down into the case.

I made it larger towards the middle of the assembly.. this i did for my 45 colt loads when i used the really big holes.

Some of the disc would not go over the factory sized hole unless i flared more than i wanted to.. I like minimal flare.. just enough to start the bullet straight .

OH you may get some 1500grit sand paper and polish the flare really shiny like chrome in the powder through expander die.. this makes smoother flares and less copper/ brass will be skimmed from the cases.

Flare 50 cases with the stock flare(expander) and you will notice shiny gold flecks on things.

maybe i am picky like that.. I also polish my expander mandrels in the rifle dies and also polish my dies.

I do not know what powder you are using but the regular auto disc works very well with bullseye and 231 as far as i know.

But like i stated earlier i modified it.

I closed up the clearances and I also enlarged the hole where the disc moves to to drop the powder down into the case.

I made it larger towards the middle of the assembly.. this i did for my 45 colt loads when i used the really big holes.

Some of the disc would not go over the factory sized hole unless i flared more than i wanted to.. I like minimal flare.. just enough to start the bullet straight .

OH you may get some 1500grit sand paper and polish the flare really shiny like chrome in the powder through expander die.. this makes smoother flares and less copper/ brass will be skimmed from the cases.

Flare 50 cases with the stock flare(expander) and you will notice shiny gold flecks on things.

maybe i am picky like that.. I also polish my expander mandrels in the rifle dies and also polish my dies.

Having a little trouble... trying to run it through one small step at a time to learn how it all fits and functions.

First, I read instructions and watched videos on setting the dies. My sizing and depriming die doesn't seem to want to deprime my 9mm cases.

1. I raised the press base to its highest point, handle all the way down.

2. Screw in the die until it touches the case plate - can't go any more, just lightly by hand.

3. Screw down locking nut.

Problem is, this isn't depriming my brass. Once, it pushed the pistol decapper out of the collet, what they call the decapper clamp. I loosened this and reset it to be flush with the top of the clamp or collet. I cannot get it to deprime any of my brass... they simply run through and are untouched. I can't thread the die itself any lower, as it's contacting the base plate, which is what it is supposed to do, I think. And I haven't tried pushing the decapper deeper into the clamp because it says it should be flush.

Am I doing something wrong? I haven't seen this as a common problem in any of the videos I've watched. Stupidly, I actually loosened the decapper clamp too much and my pistol decapper/rod fell out, straight through my base and into the hollow center of the piston. lol. So I've had to disassemble the whole damn press and turn it upside down to get it to come back out. That's ok, though, since I need to tear it down and run to Lowe's to get some sturdier bolts to bolt it down.

So before I move on, is it ok for me set the pistol decapper rod slightly deeper inside the collet or decapper clamp? So that it fits lower inside the case and pushes the primers out?

More questions to come, I'm sure. lol

First, I read instructions and watched videos on setting the dies. My sizing and depriming die doesn't seem to want to deprime my 9mm cases.

1. I raised the press base to its highest point, handle all the way down.

2. Screw in the die until it touches the case plate - can't go any more, just lightly by hand.

3. Screw down locking nut.

Problem is, this isn't depriming my brass. Once, it pushed the pistol decapper out of the collet, what they call the decapper clamp. I loosened this and reset it to be flush with the top of the clamp or collet. I cannot get it to deprime any of my brass... they simply run through and are untouched. I can't thread the die itself any lower, as it's contacting the base plate, which is what it is supposed to do, I think. And I haven't tried pushing the decapper deeper into the clamp because it says it should be flush.

Am I doing something wrong? I haven't seen this as a common problem in any of the videos I've watched. Stupidly, I actually loosened the decapper clamp too much and my pistol decapper/rod fell out, straight through my base and into the hollow center of the piston. lol. So I've had to disassemble the whole damn press and turn it upside down to get it to come back out. That's ok, though, since I need to tear it down and run to Lowe's to get some sturdier bolts to bolt it down.

So before I move on, is it ok for me set the pistol decapper rod slightly deeper inside the collet or decapper clamp? So that it fits lower inside the case and pushes the primers out?

More questions to come, I'm sure. lol

NM, I got the depriming working. Just had to get a bit more aggressive in tightening down the overall die. Working well... next step, setting bullet OAL. Gonna be tough... can't find my calipers.

9MM as i read.\

Calipers no where to be found,, Not an issue that can't be worked around.

Seat a bullet where it looks right to your eyes and then chamber it ..If the slide does not fully close then seat it deeper until it closes.

Now you must not have a flared case mouth when testing.

You can also smoke the bullet or use a sharpie to color the bullet to see if it is getting into the lands.

If you find the lands and back off of them you will be ok.

Build about 4 rounds and stick them into the magazine and chamber and un chamber all of them to see if they all cycle up the ramp and into the chamber without issue.

Adjust seating depth until all runs smooth through the gun.

Calipers no where to be found,, Not an issue that can't be worked around.

Seat a bullet where it looks right to your eyes and then chamber it ..If the slide does not fully close then seat it deeper until it closes.

Now you must not have a flared case mouth when testing.

You can also smoke the bullet or use a sharpie to color the bullet to see if it is getting into the lands.

If you find the lands and back off of them you will be ok.

Build about 4 rounds and stick them into the magazine and chamber and un chamber all of them to see if they all cycle up the ramp and into the chamber without issue.

Adjust seating depth until all runs smooth through the gun.

I went to Lowe's and bought some calipers.

Interesting... my Lyman reloading manual doesn't give me OAL for 115g FMJ 9mm, but I set my OAL to match the factory loads I had handy from Winchester and TulAmmo at about 1.15... some of the factory loads were up to 1.17, but mine are all in the 1.15 range.

Here's my first try:

Hmmm.... something tells me I forgot something important?

Interesting... my Lyman reloading manual doesn't give me OAL for 115g FMJ 9mm, but I set my OAL to match the factory loads I had handy from Winchester and TulAmmo at about 1.15... some of the factory loads were up to 1.17, but mine are all in the 1.15 range.

Here's my first try:

Hmmm.... something tells me I forgot something important?

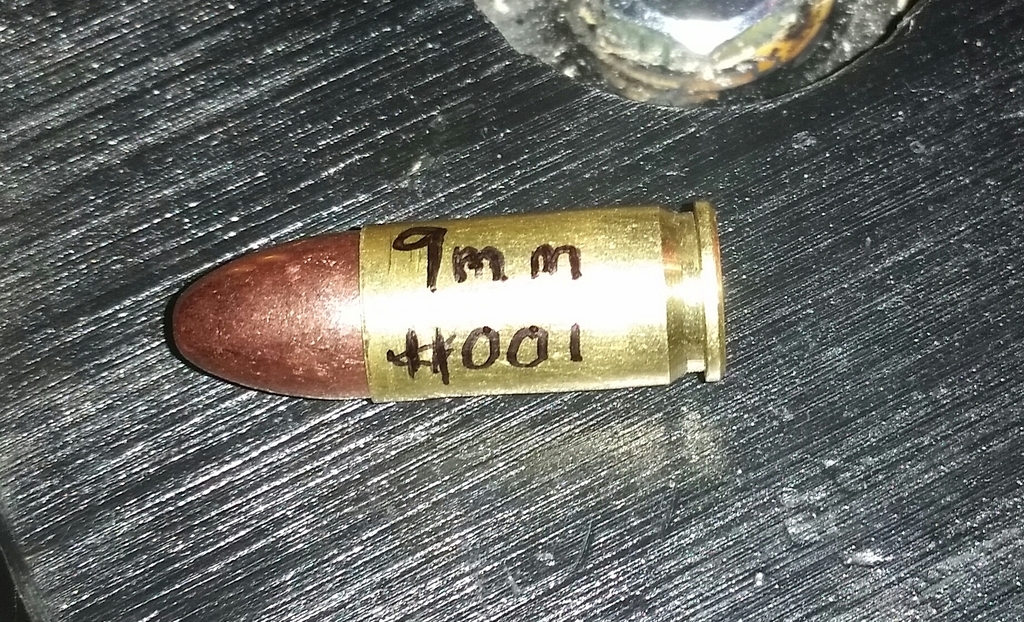

Fixed the problem and here's my first "production" unit.

Commemoratively numbered, of course.

Commemoratively numbered, of course.

Similar threads

Oklahoma City

WTB Dillon 550 conversion kit

- Replies

- 0

- Views

- 45

- Replies

- 0

- Views

- 393

Oklahoma City

Needed Lyman Lubasizer sizing die

- Replies

- 1

- Views

- 79

Latest posts

-

-

-

-

-

-

-

-

Want To Buy Wanted to Buy Pre Lock Vintage or Older S&W Smith and Wesson Revolver

- Latest: sushi & pistols

-

-

-

-

-

-

-

-

-

Join the conversation!

Join today and get all the highlights of this community direct to your inbox. It's FREE!

- Curated content sent daily, so you get what's interesting to you!

- No ads, no large blocks of text, just highlights for easy digest

- It's all totally free!

Enter your email address to join:

Thank you for joining!

Already

a member? Click here to log in

many more to come

many more to come