Something to do on some ammo you have had loaded for over a month,

This was discussed in another thread but it was based on ammo loaded much longer than 1 month.

Take a couple cases that were loaded some time back and stick then into the press and seat the bullets .002 or .005" deeper.

I found a lot of my loaded stored ammo would need considerable pressure to seat the bullet deeper..and to initially move the stored ammo's projectile you would hear the pop. Just before the bullet would start moving.

Now if the ammo sat 1 day and you set the bullet back .002" it would feel smooth and gradual.

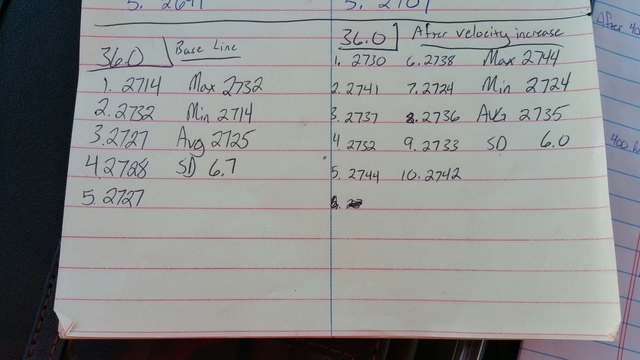

In other words the bullet could be actually bonding to the case a bit and making pressures and speeds increase.

Just something to try out on some old loaded ammo. I have no idea if 1 month or 6 months is long enough to test..But something to test.

This was discussed in another thread but it was based on ammo loaded much longer than 1 month.

Take a couple cases that were loaded some time back and stick then into the press and seat the bullets .002 or .005" deeper.

I found a lot of my loaded stored ammo would need considerable pressure to seat the bullet deeper..and to initially move the stored ammo's projectile you would hear the pop. Just before the bullet would start moving.

Now if the ammo sat 1 day and you set the bullet back .002" it would feel smooth and gradual.

In other words the bullet could be actually bonding to the case a bit and making pressures and speeds increase.

Just something to try out on some old loaded ammo. I have no idea if 1 month or 6 months is long enough to test..But something to test.