The neckties Trump sells are still imported from China though.

We need a necktie tariff.

We need a necktie tariff.

There will be no tariffs on apparel, perfume, some beverages, appliances and household items including articles of furniture, because who would even do that? I mean who? Why would anybody even do that? Only somebody stupid would do that.The neckties Trump sells are still imported from China though.

We need a necktie tariff.

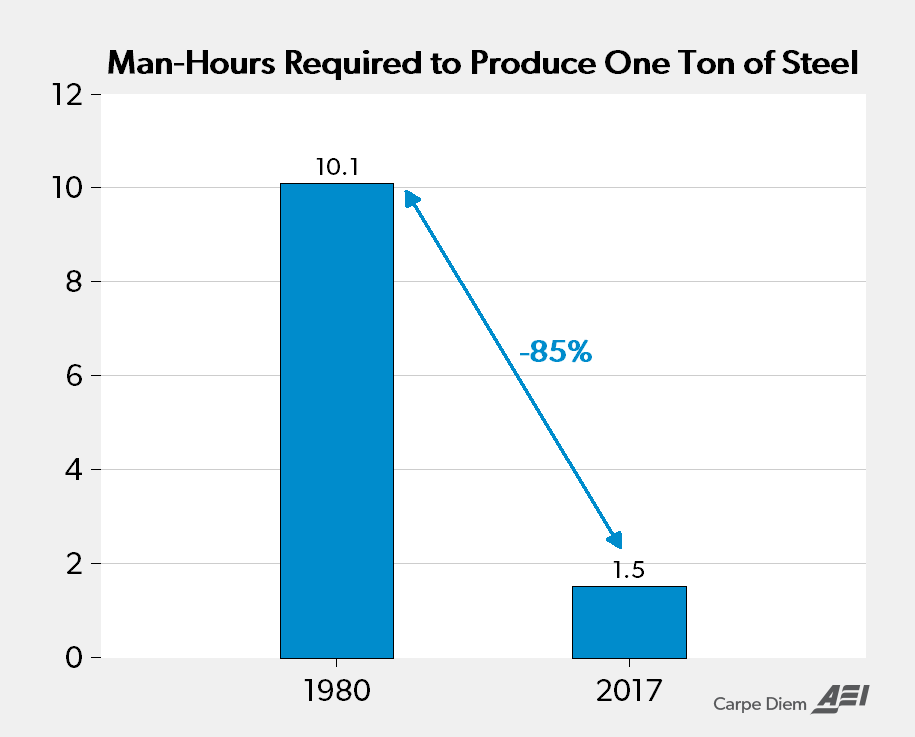

This does nothing to explain why we are still importing more steel than we make. With a man hour reduction of that magnitude I find it downright laughable that they can ship steel from China and other places half way around the globe cheaper than we can make it. Nope. Ain't buying it...The main reason for the loss of US steel jobs is a huge increase in worker productivity, not imports, and the jobs aren’t coming back

In the 1980s, American steelmakers needed 10.1 man-hours to produce a ton of steel; now they need 1.5 man-hours (see chart above), says Joe Innace of S&P Global Platts. Most American steel is now made at super-efficient mini mills, which use electric arc furnaces to turn scrap metal into steel. (Traditional integrated steel mills make steel from scratch, feeding iron ore and coking coal into blast furnaces.)

Some mini-mills need just 0.5 man-hours to produce a ton of steel, Innace says. Increased productivity means today’s steel mills don’t need as many workers. Steel industry employment peaked at 650,000 in 1953. By the start of this year, U.S. steelmakers employed just 143,000.

Someone should tell Trump about Voestalpine AG’s steel plant in Austria, which reveals the reality of steel production and jobs. A Bloomberg News story from June 20, 2017 offered a fascinating look at how a modern plant can now produce high-quality steel with few workers. The plant in Donawitz, a two-hour drive from Vienna, needs all of 14 employees to make 500,000 tons of steel wire a year. The same mill in the 1960s would have needed as many as 1,000 workers to produce a similar amount albeit of lesser quality.

“We have to forget steel as a core employer,” Voestalpine CEO Wolfgang Eder told Bloomberg. “In the long run we will lose most of the classic blue-collar workers, people doing the hot and dirty jobs in coking plants or around the blast furnaces. This will all be automated.” Voestalpine long ago concluded it couldn’t compete with the low-cost blast furnaces of the Chinese and others. So it has invested in technology to reduce costs while competing to make high-quality niche products. The so-called U.S. mini-mills have done something similar to stay competitive. Tariffs will let those mills raise prices and profits, but they won’t add much more than a token number of new jobs.

The policy point is that Mr. Trump’s tariffs are trying to revive a world of steel production that no longer exists. He is taxing steel-consuming industries that employ 6.5 million and have the potential to grow more jobs to help a declining industry that employs only 140,000.

And yet it is. Employing people is expensive; most estimates put it at an average of ~2½ times their annual wage when you account for benefits and such. Given that the steel industry is heavily unionized, it's probably higher than that for them (pension costs and such that don't exist in the non-union world). Throw in the cost of energy here as compared to China and it's easy to see where the costs add up quickly. And shipping is surprisingly cheap, especially right now when shipping capacity exceeds demand--there are shippers willing to work at a loss because the loss is less than the loss of just sitting at anchor, as fixed costs have to be met whether the boat is moving or not.This does nothing to explain why we are still importing more steel than we make. With a man hour reduction of that magnitude I find it downright laughable that they can ship steel from China and other places half way around the globe cheaper than we can make it. Nope. Ain't buying it...

First, we dont import more steel than we produce.This does nothing to explain why we are still importing more steel than we make. With a man hour reduction of that magnitude I find it downright laughable that they can ship steel from China and other places half way around the globe cheaper than we can make it. Nope. Ain't buying it...

"needs all of 14 employees to make 500,000 tons of steel wire a year. The same mill in the 1960s would have needed as many as 1,000 workers to produce a similar amount albeit of lesser quality."And yet it is. Employing people is expensive; most estimates put it at an average of ~2½ times their annual wage when you account for benefits and such. Given that the steel industry is heavily unionized, it's probably higher than that for them (pension costs and such that don't exist in the non-union world). Throw in the cost of energy here as compared to China and it's easy to see where the costs add up quickly. And shipping is surprisingly cheap, especially right now when shipping capacity exceeds demand--there are shippers willing to work at a loss because the loss is less than the loss of just sitting at anchor, as fixed costs have to be met whether the boat is moving or not.

Cost issue: Nope. Didn't miss it at all. Just chose not to address it.First, we dont import more steel than we produce.

In 2017 we produced 81.6 million tons and imported only 35.4 million tons of steel.

Only 3-4% of the steel we imported came from China.

Second, you wildly missed the point.

Because modern steel mills are so automated, only a few thousand jobs can possibly be created even if we eliminated imports completely.

And those jobs would come at the expense of hundreds of thousands of jobs in industries that consume steel, like automakers and oh, I dont know motorcycle manufacturers?

Like I said, we've been here before.

Nixon tried steel tariffs, Dubya tried them and lost more jobs than gained.

Trump never read a book but he claims to be an expert,

Don't believe it.

Enter your email address to join: