I love the bottom knife...I want one!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

that giraffe bone baby is too much...its perfect...what are the dimensions ??? and the price ???

that giraffe bone baby is too much...its perfect...what are the dimensions ??? and the price ???

9 1/2" total with about a 4 1/2 blade give or take. Probably start on the sheath tomorrow, I am going to list for 350.00

I had an custom order for a caping knife with a copper bolster so I decided to just use copper for both projects I had going this weekend. The surprise to me, anyway was how the black ash burl turned out, I wanted mesquite burl for this knife but couldn't get my hands on any, good thing to because these turned out sweet.

1st up is the caping knife 7" total with a 2 3/4" blade @ 1/8" stock thickness 0-1 tool steel. Light acid etch on blade with perimeter mirror polished.

handle is copper bolster, copper pins (#6 ground wire) and stabilized California Buckeye Burl.

didn't notice until after pics I left some polishing compound on the pin just ignore it...lol.

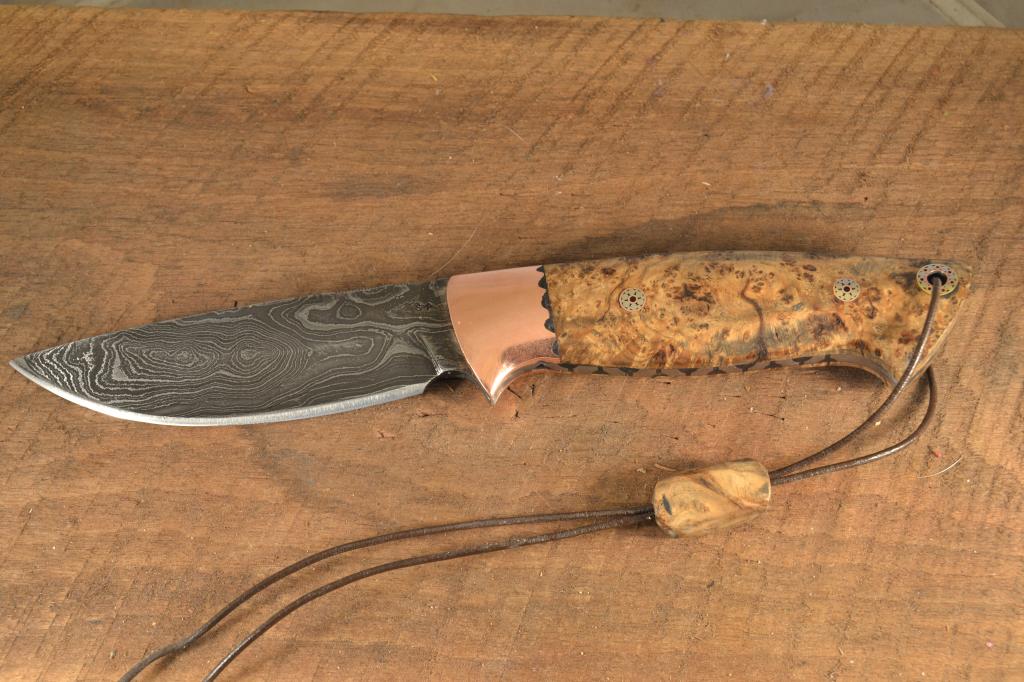

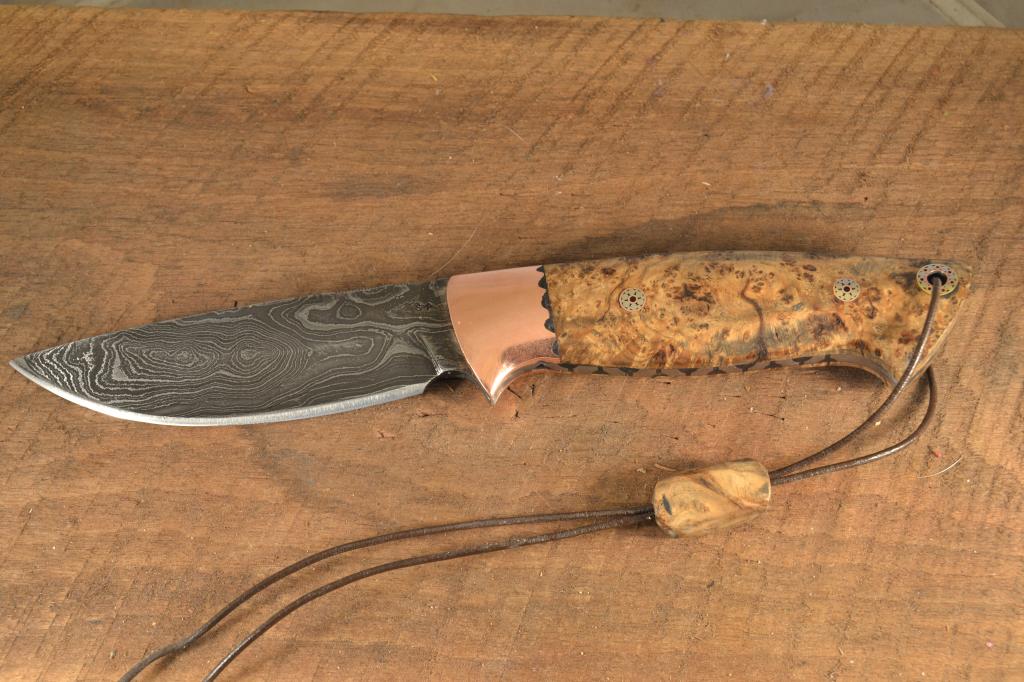

2nd a 9.5" hunter with 4.5" blade cut from 3/16" Alabama Damascus.

handle is copper bolster, stabilized Black Ash Burl, pins are a combination of copper, brass and nickel silver.

1st up is the caping knife 7" total with a 2 3/4" blade @ 1/8" stock thickness 0-1 tool steel. Light acid etch on blade with perimeter mirror polished.

handle is copper bolster, copper pins (#6 ground wire) and stabilized California Buckeye Burl.

didn't notice until after pics I left some polishing compound on the pin just ignore it...lol.

2nd a 9.5" hunter with 4.5" blade cut from 3/16" Alabama Damascus.

handle is copper bolster, stabilized Black Ash Burl, pins are a combination of copper, brass and nickel silver.

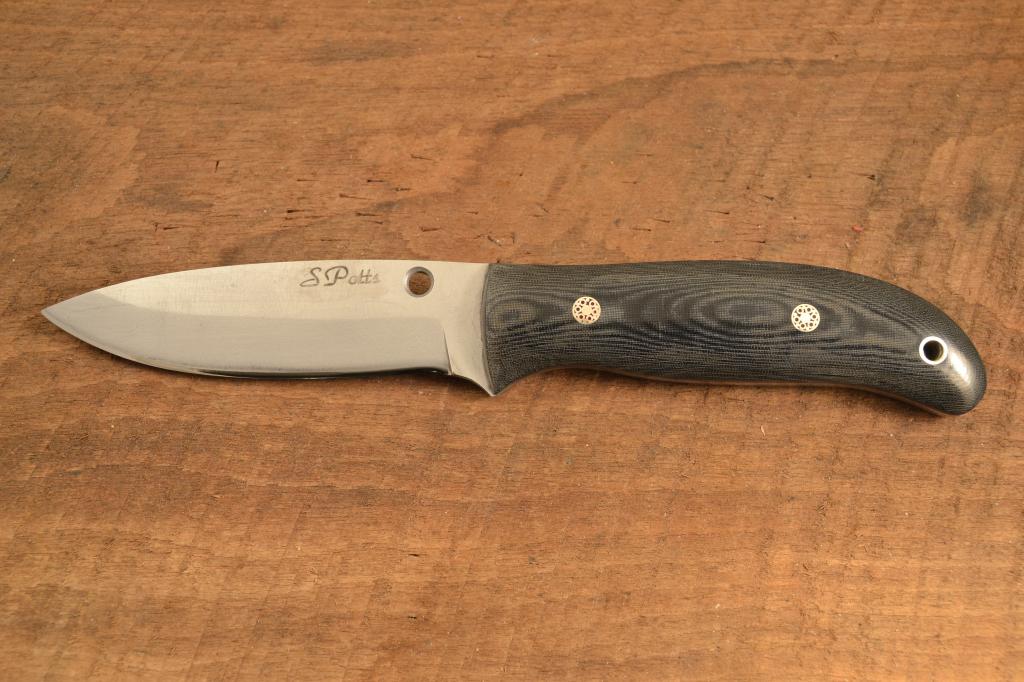

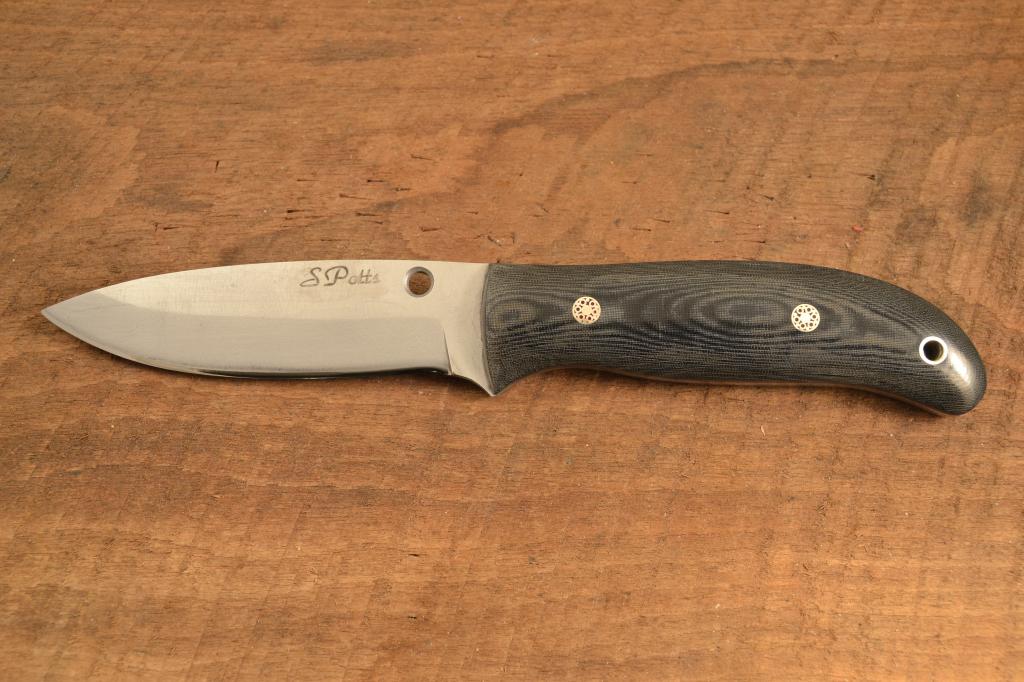

Yes this knife looks like several of the over the counter knives out there, this one was custom made to specifications provided by another good repeat customer or I probably wouldn't even of made it. I am willing to take customer sketches and make that knife within reason, I know some guys/knife makers wont do that, but to each there own right, and really how much more custom could a knife be than to build it to the exact customer sketch...lol.

This one is kind of quick and dirty, hand sanding just one level at 220g then it went straight into sand blaster for a good frosting, handle is bullet proof linen micarta, blade is 5/32 0-1 tool steel, should make a really good beater while standing out a little from the crowd.

This one is kind of quick and dirty, hand sanding just one level at 220g then it went straight into sand blaster for a good frosting, handle is bullet proof linen micarta, blade is 5/32 0-1 tool steel, should make a really good beater while standing out a little from the crowd.

Similar threads

- Replies

- 12

- Views

- 706

- Replies

- 13

- Views

- 1K

- Replies

- 29

- Views

- 2K

Latest posts

-

-

-

Is there a tape that will stay stuck inside a concrete tornado shelter?

- Latest: Oklahomabassin

-

-

Baofeng UV-5R, Ham Radio, What can I listen in on in OKC?

- Latest: Beautiful Mulberry

-

-

-

-

-

-

-

-

-

Join the conversation!

Join today and get all the highlights of this community direct to your inbox. It's FREE!

- Curated content sent daily, so you get what's interesting to you!

- No ads, no large blocks of text, just highlights for easy digest

- It's all totally free!

Enter your email address to join:

Thank you for joining!

Already

a member? Click here to log in